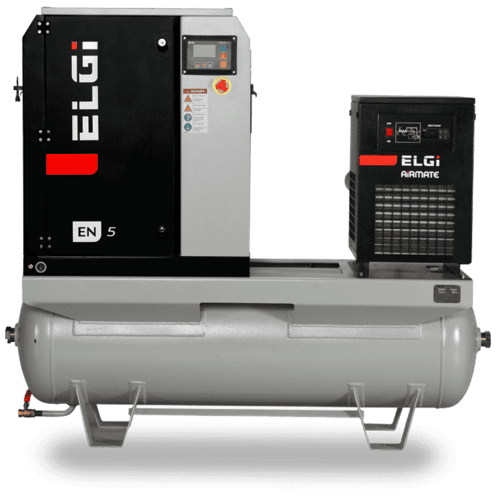

EN Series Screw Air Compressors 2.2-45 kW

Product Details:

- Usage industrial

- Product Type Screw Air Compressor

- Color Black

- Type Of Compressor Screw

- Configuration Portable

- Power Source Ac Power

- Silent Yes

- Click to View more

X

EN Series Screw Air Compressors 2.2-45 kW Product Specifications

- Yes

- Portable

- Ac Power

- Screw Air Compressor

- Oil-Free

- industrial

- Screw

- Black

EN Series Screw Air Compressors 2.2-45 kW Trade Information

- 7-10 Days

Product Description

Screw air compressors are a type of positive displacement compressor that works by trapping air between two meshing helical screws, known as rotors. These compressors are widely used in various industries for applications such as powering pneumatic tools, manufacturing processes, and providing compressed air for various purposes.

Product details

|

Max Pressure |

7.2 - 12.7 bar |

|

Noise |

64 db |

|

Working Pressure |

7 - 12.5 bar g |

|

Weight |

150 Kg |

|

Model Name/Number |

En 5 |

|

Brand |

ELGi |

|

Horse Power |

5.5 Hp |

1. Best-in-class reliability

The EN Series Compressor is crafted to incorporate all operational elements and the compressor itself within a unified housing, offering a compact footprint, exceptional reliability, and minimal maintenance needs.

2. Compact and elegant design

The EN Series Compressor features a compact design driven by ELGis energy-efficient eta-V profiles. This innovative design ensures zero leakage by seamlessly integrating components and connections.

3. Energy-efficient, encapsulated airends

The EN Series Compressor is equipped with ELGis exclusive assembly, ensuring energy efficiency, minimal pressure drop throughout the system, and a compact, silent operation.

4. Best-in-class maintenance and operating cost

The EN Series Compressor boasts an advanced air filtration system, ensuring that the internal components remain free from contaminants. This cleanliness not only preserves optimal cooling efficiency but also reduces the need for frequent oil filling, thereby extending the lifespan of consumables.

5. Efficient air-oil separation

The air-oil separation process in our EN Series Compressor occurs through a three-stage mechanism. In the first stage, the air-oil mixture impacts the circumferential area of the tank. Following that, in the second stage, the mixture undergoes deceleration to eliminate oil particles. Finally, in the third stage, air containing minimal oil traces proceeds to the spin-on separator for further purification.

6. Optional variable speed drives for energy efficiency

The ELGi EN Series Compressor adjusts its output to meet the demand by modulating motor speed. As demand decreases, the compressor reduces power consumption over time, effectively minimizing the need for frequent load-unload cycles and resulting in energy savings.

7. Indigenously designed Neuron control system offering operating data and safety measures

The Neuron XT controller is specifically crafted and engineered to serve as a streamlined control solution for our EN Series. It empowers you to effortlessly monitor and manage overall performance, providing user-friendly service indications, malfunction alarms, and safety shutdowns.

8. Highly efficient belt drive transmission

The ELGi EN series guarantees highly efficient power transmission over extended distances.

FAQs of EN Series Screw Air Compressors 2.2-45 kW:

Q: What is an EN Series Screw Air Compressor?

A: An EN Series Screw Air Compressor is a type of industrial air compressor that uses a screw-type mechanism to generate compressed air. It is available in a range of power ratings from 2.2-45 kW and is designed to be both portable and silent.Q: What type of power source is required to operate an EN Series Screw Air Compressor?

A: An EN Series Screw Air Compressor requires an AC power source.Q: What color is an EN Series Screw Air Compressor?

A: An EN Series Screw Air Compressor is available in black.Q: Does an EN Series Screw Air Compressor require oil for lubrication?

A: No, an EN Series Screw Air Compressor is an oil-free compressor and does not require oil for lubrication.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free